ErP Directive compliant fans

-

Construction

- Supporting frame in drawn galvanized steel sheet, with radius inlet cone. Models 63 and 71 supporting frame in drawn steel sheet, with radius inlet cone, epoxy coated

- Axial impeller with aerofoil profi leblades in polymer or die-cast aluminium and die-cast aluminium hub. Variable pitch angle in still position with setting means. Balanced according to ISO 1940

- Execution 5 (impeller directly coupled to motor shaft)

- Air flow from motor to impeller

- Inlet protection guard and motor support in steel rod, epoxy coated. According to EN ISO 12499 norm.

Accessories

- Gravity shutter (S)

- Spacer manufactured in epoxy painted steel sheet (D)

- Impeller side protection guard manufactured according to UNI ISO 12499 rules and protected against atmospheric agents (R)

-

Construction

- Casing in galvanized steel sheet with fixing flanges of standardized dimensions

- Single-phase and three-phase electric external rotor motor, IP44, class B/F, with internal thermal protection, suitable for speed control (using the suitable speed regulators shown in this catalogue)

- Backward curved impeller for models 4×2, 5×2,5 and 5×3, forward curved impeller for models 6×3, 6×35 and 7×4

- External electric connection box, in a self-extinguishing techno-polymeric box, resistant to atmospheric agents with IP55 protection.

Accessories

- Speed regulators

- Silencers

- Flexible connections

-

Construction

- Volute casing in steel sheet, protected against atmospheric agents by epoxy paint

- Aerodynamically shaped inlet cone in steel sheet, protected against atmospheric agents by epoxy paint

- Single inlet backward curved wheel with high efficiency, manufactured in steel sheet and epoxy painted

- For high rotational speed, versions in class 3 are foreseen

- For execution 1 – 9 – 12: mono-block support in cast iron with ball bearings, , designed for easy lubrication

- Pulleys, belts and motor support. Belt protection guard

- Asynchronous three-phase motors according to international standards IEC 600034, IEC 60072, EMC 2004/108/CE, LVD 2006/95/CE, CE marked, IP 55, class F, suitable to S1 service (continuous working at constant load).

Accessories

- Condensation drain hole (TS)

- Inspection door (PI)

- Inlet counter-flange (CFA)

- Outlet counter-flange (CFP)

- Inlet protection guard (RA)

- Outlet protection guard (RP)

- Inlet flexible connector (GA)

- Outlet flexible connector (GP)

- Inlet vane control

- Outlet setting shutter

- Anti-vibration mounts

-

Construction

- Volute casing in die cast aluminium, protected against atmospheric agent by epoxy paint. Support feet are integral part of the casing

- Single inlet, open blade, radial impeller in die cast aluminium

- Execution 5 (with impeller directly coupled to flanged motor)

- Fixed orientation RD 270°

- Asynchronous three-phase or single-phase motors according to international standards IEC 600034, IEC 60072, EMC 2014/34/UE, LVD 2014/35/UE, CE marked, IP 55, class F, suitable to S1 service (continuous working at constant load).

Accessories

- Inlet protection guard manufactured according to UNI 12499 norm and protected against the atmospheric agents.

-

Construction

- Casing in steel sheet, protected against atmospheric agents by epoxy paint

- Single-phase electric ball-bearing motor with non-self resetting thermal cut-out, particularly suitable for speed regulation

- Backward curved centrifugal impeller with high efficiency and low noise level. Statically and dynamically balanced according to ISO 1940

- Down stream guide vanes, for improved efficiency

- External electric connections enclosed in a terminal box in self-extinguishing technopolymer, with IP54 protection

- Comply with EN 60335-2-80, B.T. 2006/95/ CE, EMC 2004/108/CE

Accessories

- Speed regulators

- Back-draught shutters

- Protection guard

- Collars for fixing to the duct

- Silencers

-

Construction

- Volute casing in steel sheet , protected against atmospheric agents by epoxy paint

- Aerodynamically shaped inlet cone in steel sheet, protected against atmospheric agents by epoxy paint

- Single inlet backward curved wheel with high efficiency, manufactured in steel sheet and epoxy painted. For high rotational speed, versions in class 3 are foreseen

- For execution 1 – 9 – 12: mono-block support in cast iron with ball bearings, , designed for easy lubrication. Pulleys, belts and motor support. Belt protection guard

- Asynchronous three-phase motors according to international standards IEC 600034, IEC 60072, EMC 2004/108/CE, LVD 2006/95/CE, CE marked, IP 55, class F, suitable to S1 service (continuous working at constant load)

Accessories

- Condensation drain hole (TS)

- Inspection door (PI)

- Inlet counter-flange (CFA)

- Outlet counter-flange (CFP)

- Inlet protection guard (RA)

- Outlet protection guard (RP)

- Inlet flexible connector (GA)

- Outlet flexible connector (GP)

- Inlet vane control

- Outlet setting shutter

- Anti-vibration mounts

-

Construction

- Volute casing with quadrangular frame, manufactured in galvanized steel sheet and protected against atmospheric agents with epoxy finish

- Single inlet, backward curved wheel with high efficiency, manufactured in galvanized steel sheet and die-cast aluminium hub

- Execution 5 (impeller directly coupled to fl anged motor), rotation RD

- Asynchronous three-phase or single-phase motors according to international standards IEC 60034, IEC 60072, EMC 2014/30/CE, LVD 2014/35/UE, CE marked, IP 55, class F, suitable to S1 service (continuous working at constant load)

Accessories

- Inlet and outlet protection guard manufactured according to UNI 12499 norm and protected against atmospheric agents

- Inlet/outlet flexible connectors

- Antivibration supports

- Inlet/outlet counterflange

- Self transformer or inverters speed controllers

-

Construction

- Volute casing in steel sheet, protected against atmospheric agents by epoxy paint

- Aerodynamically shaped inlet cone in steel sheet, protected against atmospheric agents by epoxy paint

- Single inlet backward curved wheel with high efficiency, manufactured in steel sheet and epoxy painted. For high rotational speed, versions in class 3 are foreseen

- For execution 1–9–12: mono-block support in cast iron with ball bearings, designed for easy lubrication. Pulleys, belts and motor support. Belt protection guard

- Asynchronous three-phase motors according to international standards IEC 600034, IEC 60072, EMC 2014/30/UE, LVD 2014/35/UE, CE marked, IP 55, class F, suitable to S1 service (continuous working at constant load).

Accessories

- Condensation drain hole (TS)

- Inspection door (PI)

- Inlet counter-flange (CFA)

- Outlet counter-flange (CFP)

- Inlet protection guard (RA)

- Outlet protection guard (RP)

- Inlet flexible connector (GA)

- Outlet flexible connector (GP)

- Inlet vane control

- Outlet setting shutter

- Anti-vibration mounts

-

Construction

- Volute casing in steel sheet, protected against atmospheric agents by epoxy paint

- Aerodynamically shaped inlet cone in steel sheet, protected against atmospheric agents by epoxy paint

- Single inlet backward curved wheel with high efficiency, manufactured in steel sheet and epoxy painted. For high rotational speed, versions in class 3 are foreseen

- For execution 1–9–12: mono-block support in cast iron with ball bearings, designed for easy lubrication. Pulleys, belts and motor support. Belt protection guard.

- Asynchronous three-phase motors according to international standards IEC 600034, IEC 60072, EMC 2004/108/CE, LVD 2006/95/CE, CE marked, IP 55, class F, suitable to S1 service (continuous working at constant load).

Accessories

- Condensation drain hole (TS)

- Inspection door (PI)

- Inlet counter-flange (CFA)

- Outlet counter-flange (CFP)

- Inlet protection guard (RA)

- Outlet protection guard (RP)

- Inlet flexible connector (GA)

- Outlet flexible connector (GP)

- Inlet vane control

- Outlet setting shutter

- Anti-vibration mounts

-

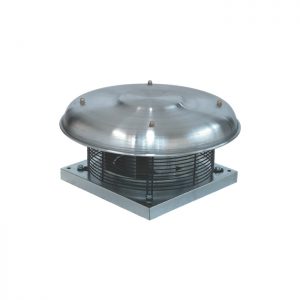

Construction

- Base frame in galvanized steel sheet

- Protection guard in drawn steel rod protected against the atmospheric agents, manufactured according to UNI 10615:1997

- Backward curved wheel in galvanized steel sheet (mod. 200 in plastic), with high efficiency and low noise level

- Upper cover in aluminium

- External rotor motor, three-phase or single phase, IP 44/B 200-250, IP 44/F 310-400, tropycalized with integral thermal protection.

Accessories

- Backdraught gravity shutter (TS)

- Silencers (GR)

- Counter base to be walled up (CB)

- Support base for corrugated roof coverings (BA)

- Inlet side Guard (RA)

- Service switch

- Speed regulator

- Delta/start switch

- Support base/Silenced reduction (PB). Not available for size 200

-

Construction

- Base frame in galvanized steel sheet

- Protection guard in drawn steel rod protected against the atmospheric agents, manufactured according to UNI 10615:1997

- Backward curved wheel in galvanized steel sheet (mod. 200 in plastic), with high efficiency and low noise level

- Outer deflector in ABS

- External rotor motor, three-phase or single phase, IP 44/B 200-250, IP 44/F 310-400, tropycalized with integral thermal protection

Accessories

- Backdraught gravity shutter (TS)

- Silencers (GR)

- Counter base to be walled up (CB)

- Support base for corrugated roof coverings (BA)

- Inlet side Guard (RA)

- Service switch

- Speed regulator

- Delta/start switch

- Support base/Silenced reduction (PB). Not available for size 200

-

Construction

- Base frame in galvanized steel sheet

- Protection guard in drawn steel rod protected against the atmospheric agents, manufactured according to UNI 10615:1997

- Backward curved wheel in galvanized steel sheet, with high efficiency and low noise level, statically and dynamically balanced according ISO 1940

- Asynchronous three-phase motor or single-phase motor manufactured according to international standards IEC 600034, IEC 60072, EMC 2004/108/CE, LVD 2006/95/ CE, CE marked, IP 55, class F

- Upper cover in ABS, with appropriate slots for motor cooling

- Outer deflector in ABS

Accessories

- Backdraught gravity shutter (TS)

- Silencer (GR)

- Support base for wawed roof coverings (BA)

- Inlet Protection Guard (RA)

- Service switch

- Support base/Silenced reduction (PB)